Background:

The heating plant in Ystad, Sweden, owned by Ystad Energi AB, produces 100 % renewable district heating. The plant has two main boilers of 10 MW each and are mainly fired by chipped branches and tops that remain after deforestation. Ystad Energi decided to invest in three ORC-turbines to become less dependent on the electricity supply via the grid, where lack of capacity have become a more frequent issue. The two 10 MW-boilers are equipped with one ORC-turbine each. The third ORC-turbine will be complemented with a 5 MW boiler.

Our solution:

Againity delivered three automated ORC-systems with a maximum capacity of 750 kW electricity prodcution. The ORC-systems enables electricity production from the boilers’ hot water. When each of the ORC-turbines are installed, the expected produced electricity is 3220 MWh annually, which corresponds to annual emission savings of 2900 CO2-equvielents when replacing European marginal electricity. Ystad Energi chose to sign a service agreement with Againity to ensure a long lifetime, minimal maintenance and optimized electricity production.

3 quick questions to Vinko Culjak, district heating manager at Ystad Energi:

1. Why did you choose to invest in an ORC turbine?

For us, it was of importance that the investment would be both profitable and sustainable. Solar cells have been hyped-up, but looking at cost calculations per kWh, it motivates an investment in an ORC-turbine. Then there is the problem of load on the electricity grid, where cogeneration is important. Many small streams make a difference in the end.

2. What gave you confidence with choosing Againity?

I’d have to say the technology and simplicity itself. With few moving parts, there’s not much that can go wrong. It’s simple and robust.

3. What would you highlight towards other heating companies looking for electricity production?

The fact that you can have your own local environmentally friendly electricity production with hot water boilers and at the same time reduce the load on the electricity grid. I would also emphasise the simplicity and robustness, which is why we chose you.

Owner: Ystad Energi AB

Location: Ystad, Sweden

Existing boilers: 2x10MW, 1x5MW

Fuel: Wood chips

Heat generation after fuel gas condensation: 110 GWh/year

Temperature boiler circuit: 140°C

Temp DH-return, after FGC, average: 58°C

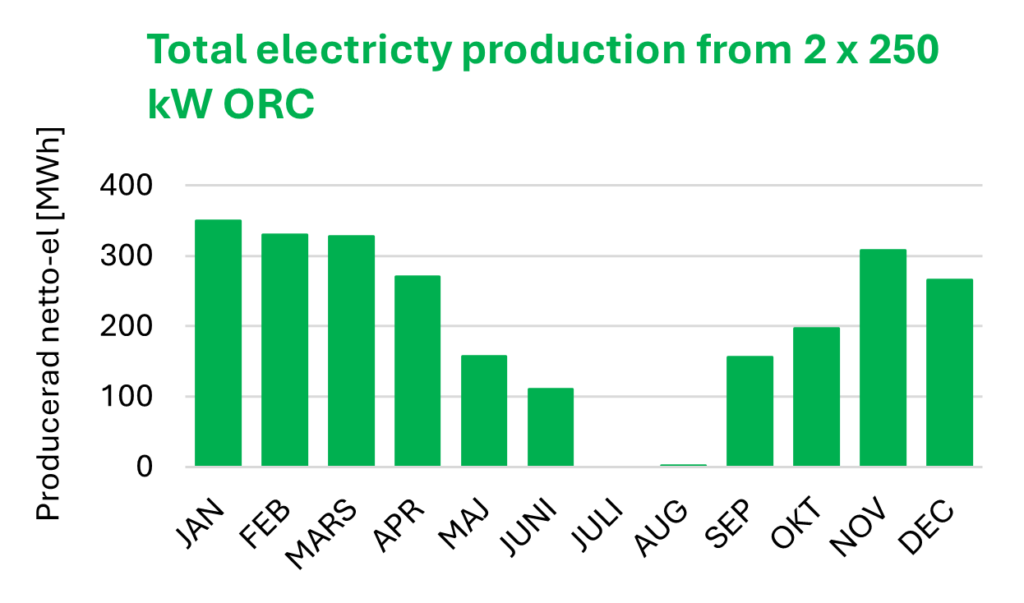

Total electricity production, 2 x ORC: 2477 MWh/år*

*The total electricity production from two ORC-turbines corresponds to emission savings of 2229 CO2-equvivalents when replacing European marginal electricity.