Swedish Organic Rankine Cycle (ORC) turbine manufacturer Againity AB has announced its first ORC delivery to Poland, in collaboration with the sales representative NPS New Power Sources Sp. z o. o. and the Polish supplier Energika Zbigniew Szamałek Sp. K.

This delivery comprises two ORC turbines with a combined output of 400 kW to a thermal power plant in Kozienice, owned by Kozienicka Gospodarka Komunalna Sp. z o. o. The installation marks an important milestone for Againity marking the eighth country to which it has supplied ORC turbines. The installation in Kozienice is also Againity’s southernmost to date.

We are expanding our offer with new services. In the past, we have mainly worked with steam power heating, combining steam boilers with steam turbines. Now we also offer highly efficient cogeneration where the hot water boilers are combined with an ORC turbine – both as a brand-new installation and for modernizing existing facilities. This is possible thanks to the partnership agreement with NPS New Power Sources, which is the basis for projects in Poland and other Eastern European countries. There are, and will continue to be in the future, new opportunities and good potential within the district heating segment.says Ewelina Szamałek-Garcarek, CEO at Energika Zbigniew Szamałek.

Increased self-sufficiency

Energika, which supplies the two hot water boilers to the heating plant, is a well-known player in Poland.

Renewable electricity from biomass not only reduces operating costs but also contributes to a significant climate benefit by replacing fossil coal power in the electricity grid.

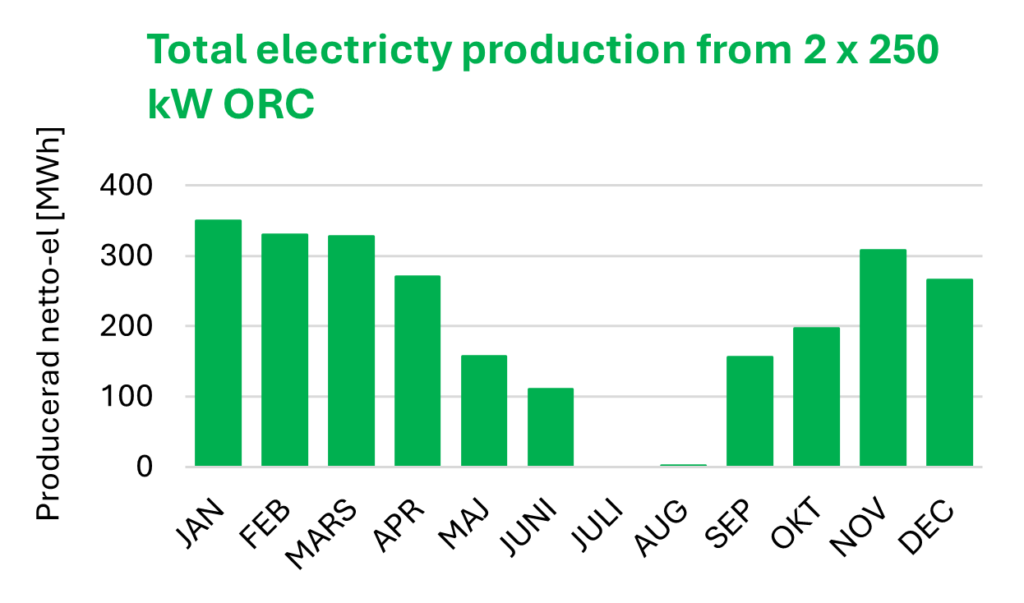

With the ORCs, the heat plant in Kozienice can increase its electricity production and self-sufficiency. At the same time, the local grid is relieved because the ORC turbine generates the most electricity when demand is at its highest.

During the cold months of the year, when the hot water boilers from Energika produce the most and electricity prices are at their highest, the ORC turbines generate maximum electricity production.

This leads to large savings and reduces the load on the power grid when the electricity demand is high.

The reduced load also creates space for the network owner to meet the electricity needs of other customers during the green transition.

The choice of ORC turbine for the heating plant in Kozienice is in line with the owners’ strategy to invest in environmentally friendly electricity.

We thank Energika and Kozienicka Gospodarka Komunalna for the trust to deliver ORC turbines and enable our own renewable electricity production at the heating plant in Kozienice. This is at a time when reduced operating costs and responsible electricity production are of increasing importance, said David Frykerås, CEO of Againity.